Our Second 3D Printer Enthusiasts Meeting, April 7th, 2012

Hello 757 Labs friends,

There has been a good influx of interest in 3D printers and related technologies in the past few months along with more members purchasing kits (RepRap variations, Makerbots, and talks of a couple PrintrBots in the area). So lets get together and share what we have and work on the ones that need some help or time to get up and running.

Date: April 07 , 2012

Time: 12:00 - 3:00 PM EST

Location: 233 W. Bute St. Norfolk, VA 23510 in the 757Labs Front Conference Area

If you have an interest or want to see some 3D printers up close come on by. If you have a kit or a completed printer, bring it with you and let's share and contribute together!

NOTE: This event is open to the public, so come on out and join us!

Microcontroller Monday Presentation

The Microcontroller Monday presentation from the 6th has been published and is viewable below. There was a great turnout for the event and I appreciate everybody's support!

-TJ

TCP Tuesdays – Networking class – March 20th, 7:30PM

7:30 PM - TCP Tuesdays (networking class)

Tue, Mar 20, 2012, 7:30 PM - 9:00 PM

757Labs, 233 West Bute St, Norfok, VA 23510

Like most 757Labs events, this is open to the public to those interested in the topic.

TCP Tuesdays, starting this week at 7:30PM

Based on a few previous message threads, and conversations at the lab, a number of people have indicated they'd be interested in a 'networking' class, in the style of Microcontroller Mondays. So, starting THIS TUESDAY (March 20), 757 Labs will be running TCP Tuesdays, hosted by yours truly.

The first night will be 7:30PM-Whenever, with a focus on getting 'setup' to learn and run labs yourself.

Please bring a non-crusty laptop (needs to be able to run a MIPS simulator - Core-series w/2GB of ram or better recommended). Linux/Windows/OS X should all work (I've not actually used Windows for this, but its 'supported'). No serial cables or other gear needed, yet.

-Adam

TV Repair Presentation with Ethan 2/28/2012 @ 7:00PM

Ethan will be doing a presentation and hands on overview of how he generally goes about diagnosing and repairing the flat panel TVs that come into the lab. Pretty much a brain dump, sharing what he knows and how he does this.

When: February 28, 2012

Time: 7:00PM EST

Where: 757 Labs, 233 W. Bute Street Norfolk, VA 23510

Background on tonights project: Recently, Matt donated a 42" plasma TV that had failed, and it will be our subject for this presentation. Ethan will be reviewing this cold, meaning that he has not looked inside the TV or pre-checked anything out other than confirming the service manual can be found on the inter-web. Ethan will cover both Plasma and LCD sets. While the one we will be looking at is a plasma TV.

Note: According to Ethan: It's not a profession, it's a hobby. My score so far: 5 wins, 2 losses. But 1 win is now a loss, but it could be a win again? So it may be something simple or maybe more complex, come and join us.

We will try to record this and if its usable will distribute at a later time/date.

Microcontroller Monday 2/6/2012 with TJ

Quick announcement for those interested in microcontrollers:

In addition to our regularly scheduled Microcontroller Monday hack sessions at the lab we are pleased to announce that the first Monday of each month, starting in February (2/6/2012), we will be upping our game and having a more formal presentation session.

The February 2012 session will be all about the different microcontrollers that are available today, what they are and an overview on what they can do and how you (yes you) can get started using them. Whether you are a novice or a seasoned veteran there will be something for everyone during this session presented by the lab's own TJ.

The sessions starts at 7:00pm EST on 2/6/2012 and is open to the public. If you have been interested this is your chance to participate.

757 Labs Class: Intro to CAD Design & 3D Modeling Saturday Oct. 29th, 1:00-3:00pm

- SketchUp is a free (also a paid version) application that can be used for all kinds of design (think tiny or large) and has been used on several projects at the lab already. Base product being free, the integration to Google Earth and its simple UI make it attractive but do not let that fool you, it is powerful and can be extended using Ruby scripting. This software works on Windows and Mac only at this time. Download a free copy here.

- AutoCAD is a paid application which is known as the most common CAD platform out there (closed source-wise). This is an industry standard type of application, and originally the flagship product from Autodesk. AutoCAD works on Windows and Mac only at this time. Download a 30 day trial here.

- This will be a 2 hour session that will start with one product, give you the working basics, Q&A, etc.. then move to the other design package. Stories, insight and open dialogue.

- At the conclusion of this you will be familiar with the applications to create and work with your own designs.

- This will also tie into the next 3D Printer (Makerbot) and Laser Cutter sessions, once you can design your own items you can print prototypes and usable pieces.

- Both applications are available within the lab on the graphics machine if you do not already have a copy.

- There are quite a few other software packages available, this session will be dealing with only the two mentioned above. It does not mean that these are better or worse than any that you have heard about, learned or used.

- If time permits we will share an overview of another application, Autodesk 123D, currently in free beta.

This session is free and open to members and guests.

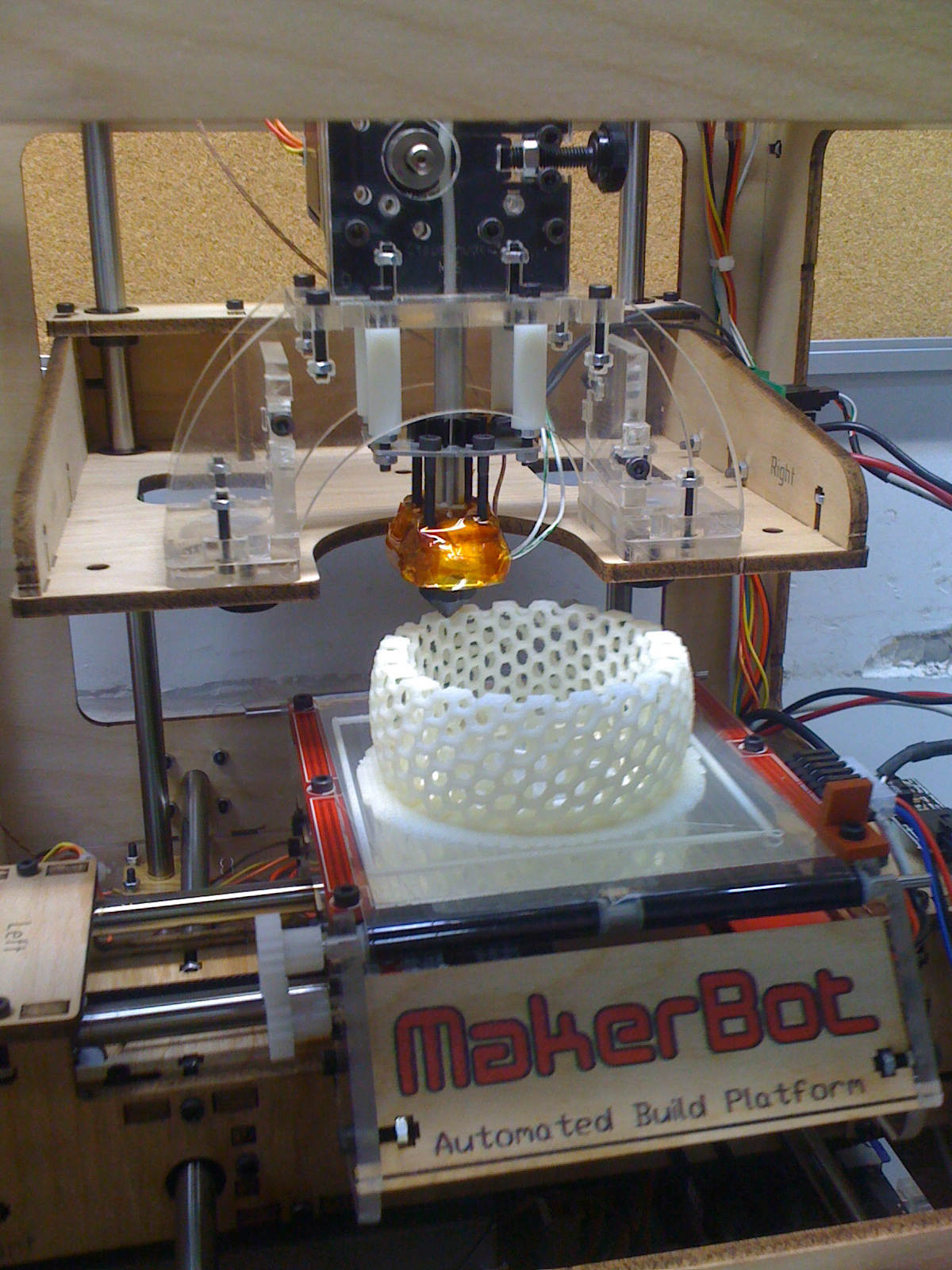

One Printer to Rule Them All or Makerbot 3D Printer Now Alive

If you have been by the lab in the last two months, you may have noticed the addition of a new 3D printer: A Makerbot Thing-O-Matic. This device grants us the ability to print objects using ABS plastic (think LEGO brick material) or PLA (a "green" alternative made from renewable material). Check out this young inventor explaining 3D printing.

So, what does this mean for the lab? It means that we now have another piece of equipment in our growing tool set to aid us in our projects. Whether serious or just goofing around (such as scanning people at the lab and printing mini-figurines), the 3D printer is available to members who have taken the training class. The first class graduated two weeks ago and now it is time for the next round for those who are interested.

A little bit about the build process and our results:

The Makerbot Thing-O-Matic is available as a do-it-yourself kit or, for a higher price, prebuilt. We chose the kit, which came in one box with everything seen below (except for the soldering iron, courtesy of Kyle).

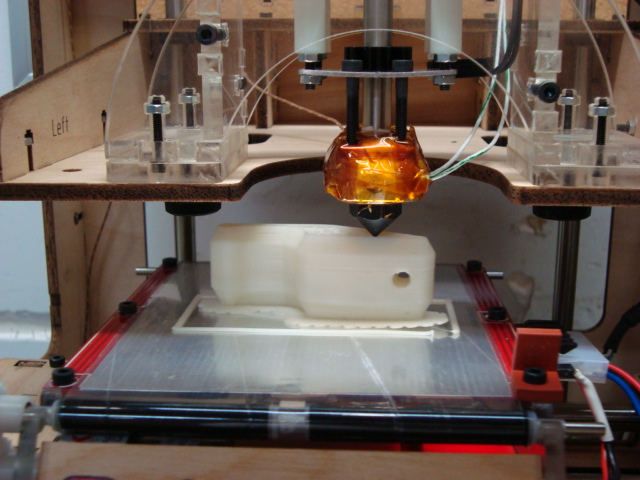

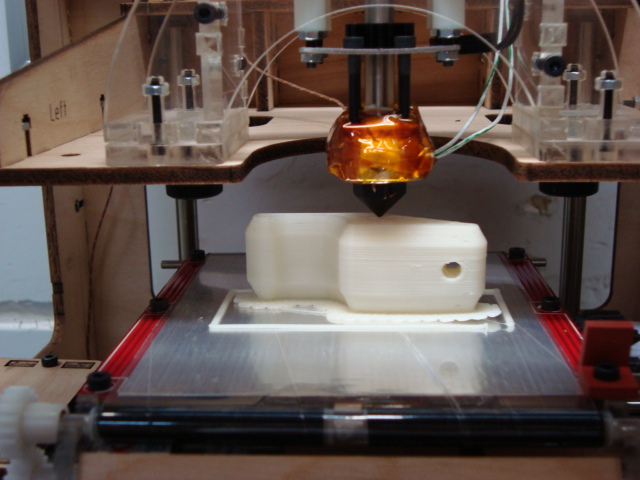

We put about 16 hours total into the build, spread out over the course of a week. In the beginning you have to choose one of three types of "build platforms," which is where the material is extruded onto. The kit provides just enough parts to build only one of the three. We elected to use the Automated Build Platform. In theory, this platform allows us to print dozens of items without any intervention. Once an object is printed, the object rolls forward using a conveyor belt where it is pushed out into a collection bucket. After the platform is cleared, the printer continues to print the next object. Our choice in platform may change over time but has been printing quite nicely over the past month as shown in the image below.

Everything went together pretty easily, for the most part, requiring only two small hacks: A single stepper motor driver cable was lengthened as it was too short and an extension connector to the power supply was built to accommodate the Automated Build Platform.

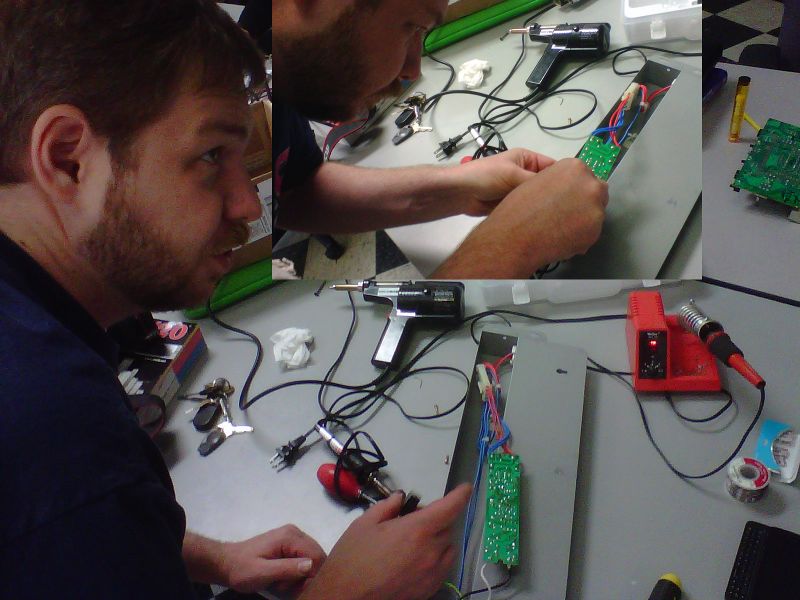

Makerbot build coming together courtesy of help from DJ Mike and Harold (once again sharing some great soldering and electronics knowledge)

Once the installation was completed we had to install and learn some new software that is used to drive the system. You can use most any CAD or modeling package (such as Google Sketch-Up, Blender, AutoCAD, etc.) for designing parts. All that is required is to export the model to .stl (stereolithography file). From here, you use ReplicatorG and open the .stl file after which you have access to a number of settings for "slicing" the model before printing with the Makerbot.

ReplicatorG uses built-in Skeinforge scripts to provide literally hundreds of minor tweaks and changes to fine tune and control your results. After completing calibration (or at least calibrating to a point we considered decent), we started moving to increasingly complicated builds. We have spent the last month running print after print, tweaking settings to provide a good starting point for those interested in printing.

We are pleased to open this tool up to more members of the lab for use in projects. If you already know any of the many CAD or modeling packages out there, you can make your own designs to print. Of course, we are also supporters of the open source design movement found over at Thingiverse. Spend some time browsing and you may find what you need already created or easily adapted!

If you want to get started, the first step is to take a class on working with the machine. More details on the specific settings we use (currently tuned for our cold environment) and how to use, best tips, etc. on our Wiki.

Enjoy and happy printing...

Saturday’s electronics class was great!

Sorry to those that missed it, but the electronics class on Saturday was informative! Kudos to Harold for putting on a great first class on electronics! No one was disappointed. For those that missed it, a video/audio recording was made of most of the presentation and is on disk viewable at the lab. We aren't planning to post it on the internet at large, it's for the benefit of those that attended, those that visit the lab, and those that are lab members.

Some photos from the event can be seen here. I'm sure others took more as well.

Basic Soldering Class Held on Saturday, March 5 2011

Our first basic soldering class presented this past Saturday was a success -- meaning no fires were started, everybody learned a lot, and no one got burnt...much. Harold did an excellent job of explaining the basics, plus he provided slides and videos illustrating many good and bad examples.

- watching some bad examples

- Harold provides soldering instructions & video commentary

- Ethan fixes a fluorescent light – “it’s a cap!”

- soldering tools

- after the lecture, soldering practice

About a dozen attendees were present, with many more showing-up later in the day to participate, even though the actual presentation was over. Items that got "fixed" via soldering included a back-light for a Cruis'n Exotica arcade game and a set of Koss headphones that previously had wire damage due to a mischievous pussycat.

Events for Saturday, March 5, 2011

Here are two events scheduled to be held at the lab on Saturday, March 5, 2011:

2:00 PM EST - basic soldering class by Harold; bring eye protection and something to solder

in Harold's words:

Date: Mon, 28 Feb 2011 19:30:14 -0500

Subject: [757labs] Class this SaturdayI finally decided to dive in and become the experimental pig for the first class! Well at least the first "hardware" related class.

This Saturday, at 2:00 PM, I plan on holding a Basic Soldering Class for anyone who wishes to show up at the Lab. With that said, if for some strange reason we are swamped, I must give preference for room to current Lab Members. That is only fair to them. I doubt we will run out of room, so please show up if you want!

The game plan is to have the herd assembled by 2 PM and the actual start time might be 15 or so minute later. The one thing that would be nice is to have a list of who all plans on showing up so I can have a roster to know when it is time to start. I won't wait all day and plan on letting 2:15 PM being the delayed start time.

For anyone who wishes to attend please bring the following if you have it:

1. Your soldering iron, station, whatever you currently use. PLEASE DO NOT RUN OUT AND BUY SOMETHING!!! Unless you really want to. There are the good bad and ugly types of irons to waste money on.

2. Hand Tools. Most soldering hand tools could be classified as side cutter diagonals or regular diagonals if you don't have those. A straight pick, tweezers, any heat shrinks etc.. Again, don't run out and buy stuff if you don't have it already.

3. Safety glasses. I am not going to demand that anyone wears a pair; however, if you do not wear any type of glasses normally ... I suggest getting a cheap pair. Remember, solder is molten metal. Your eyes do not like it. Burns to your skin are one thing ... burns to your eyes are something you more than likely wont recover from.

4. If you have any type of circuit kits or solder breadboards etc.. that you would like to work on, please bring them. If you don't have anything, please try to snag a cheap one from Radio Shack to play with. Also, if you have some old components like resistors etc.. drag them along so you can have something to solder on.

5. Solder. If you have your own type that you are used to working with bring it. If not, I should have plenty for everyone to play with.

6. Solder wick / Solder sucker. This is something that would be nice to have, but it is not required. We can pass around what we have.

7. If you have a board vise or any other sort of device that you use to hold circuit cards etc.. that would make life easier on you. If not, we will do it old school.

The objective to the course is not to turn everyone into a uber solder dude but to at least give you some insight and hands on experience to allow you to enhance your current skill set. Since I just decided to get stupid and give a class (oh joy!) I don't really have a course written up so please handle the lack of continuity and we will all get through it.

8:00 PM EST - game development meeting by Matt (cyberflux); bring your ideas

in Matt's words:

Date: Mon, 28 Feb 2011 19:20:12 -0500

Subject: [757labs] Game Developers Team (March 5)I am looking to have a game.dev meeting this Saturday for those interested in creating games at the Lab. Those who are interested feel free to show up sometime around 8pm or so, but I should be there earlier. Currently I am loading services on an older dual Xeon 2 server that will host development environments for Net applications. There is currently no defined hardware for the group so there is flexibility in what platform to go with, however most have been looking at diving into the mobile device market. Any input prior to the gathering is welcomed.

Hope to see some people there! Cheers!